Automotive (Radiator and Air Conditioner)

Precision Parts for Automotive Plastic Components

At H.H. Precision Mould Sdn. Bhd. (HH), we apply our state of the art technology, strict quality controls and tremendous attention to detail to every automotive component we produce:

- Our facilities are equipped with the up to date tools and technologies to respond quickly to our customers‘ needs for automotive plastic components.

- Our plastic injection molding plant is equipped to run 24 hours a day, 5.5 days a week to ensure on time delivery injected plastic parts.

- We are a one-stop shop, able to handle processes relate from components design to production to assembly of final product.

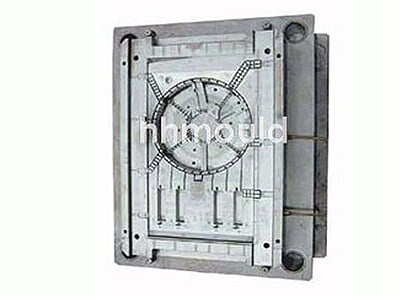

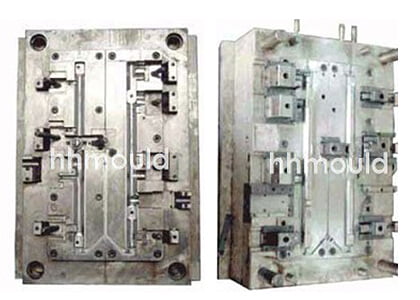

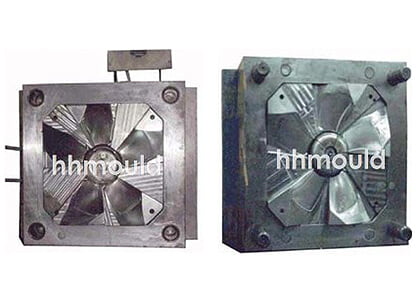

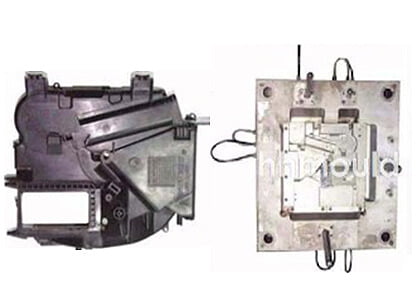

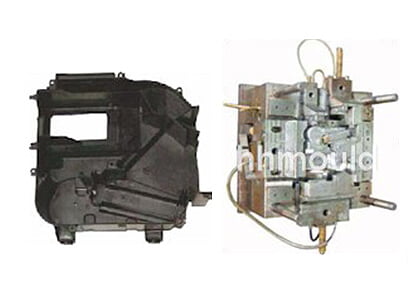

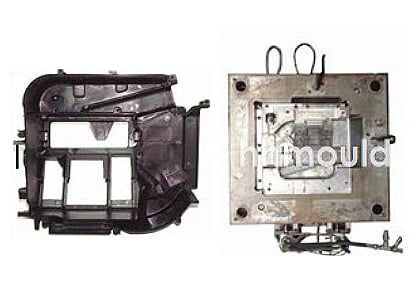

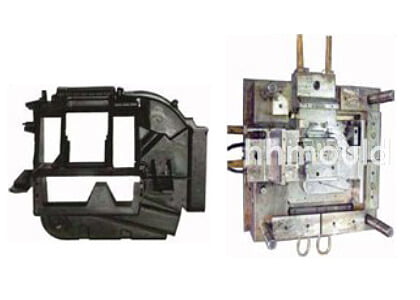

Photos: Air conditional and radiators plastic injection moulded parts manufacture by H.H. Precision Mould Sdn. Bhd.

A Company that Understands the Automotive Plastic Industry

At HH, we keep on learning. We keep up to date on innovations in the industries that we serve and adapt and improve our processes to meet the ever-changing needs of our clients.

- In view of fuel efficiency increase, market has a demand to reduce the weight of vehicles.

- Lighter automotive plastic components have become necessary to the industry’s efforts to lower the weight of cars and trucks.

- The use of automotive plastic components has brought other benefits to car manufacturers.

- Plastics offer production versatility and increased life span over steel which is susceptible to corrosion.

- Automotive plastic components are so adaptable that they are turning up just about everywhere in a vehicle.

- Any driver or passenger can see the plastic parts in the interior of a vehicle, but plastics are present throughout, in lights, bumper systems, exterior body panels, fenders, sensors and even in engines.

As the automotive industry finds new uses for plastics, HH finds itself on the leading edge of automotive plastic components manufacturing, developing processes that use our injection molding technology and new elastomers and polymers to produce high-quality products .

Background

H.H. Precision Mould Sdn. Bhd. is specializing in making automotive components for both radiators & air conditioning system in Malaysia. With the collaboration of BASF, we produced the first plastic radiator 30 years ago.

Today, we have developed radiator tanks for our national car such as Proton and Perodua, also for export model such as Renault & Australia model for Holden.

Our technical knowledge in application of high heat, hydrolysis resistant materials coupled with specialized tool for this application has won us many customers.

Summary of the type of cars model of automotive components for both radiators & air conditioning system we have manufactured and injected:

Holden

Renault

Proton

- Waja (Year:2000)

- Persona (Year:2003)

- Exora (Year:2009)

- Satria

- Savvy (Year:2005)

- Gen-2 (Year:2003)

- Wira

- Saga

- Exora Turbo (2011)

Perodua

- Myvi (Year:2005)

- Viva (Year:2007)

- Kancil (Year:1992)

Product

Automobile Radiator Tanks

HH designed and build the first Malaysian plastic radiator tank tops for Proton ( Malaysia national automobile manufacturer). With the collaboration of BASF we produced the first plastic radiator 15 years ago. Today, we have developed tanks of many variants for Proton, Perodua, Diahatsu, Toyota , Citroen, and many others. Our technical knowledge in application of high heat, hydrolysis resistant materials coupled with specialised tool for this application has won us many customers. We build products that will meet Proton standard, Toyota standard.

Product

Automotive Air Conditioner Component