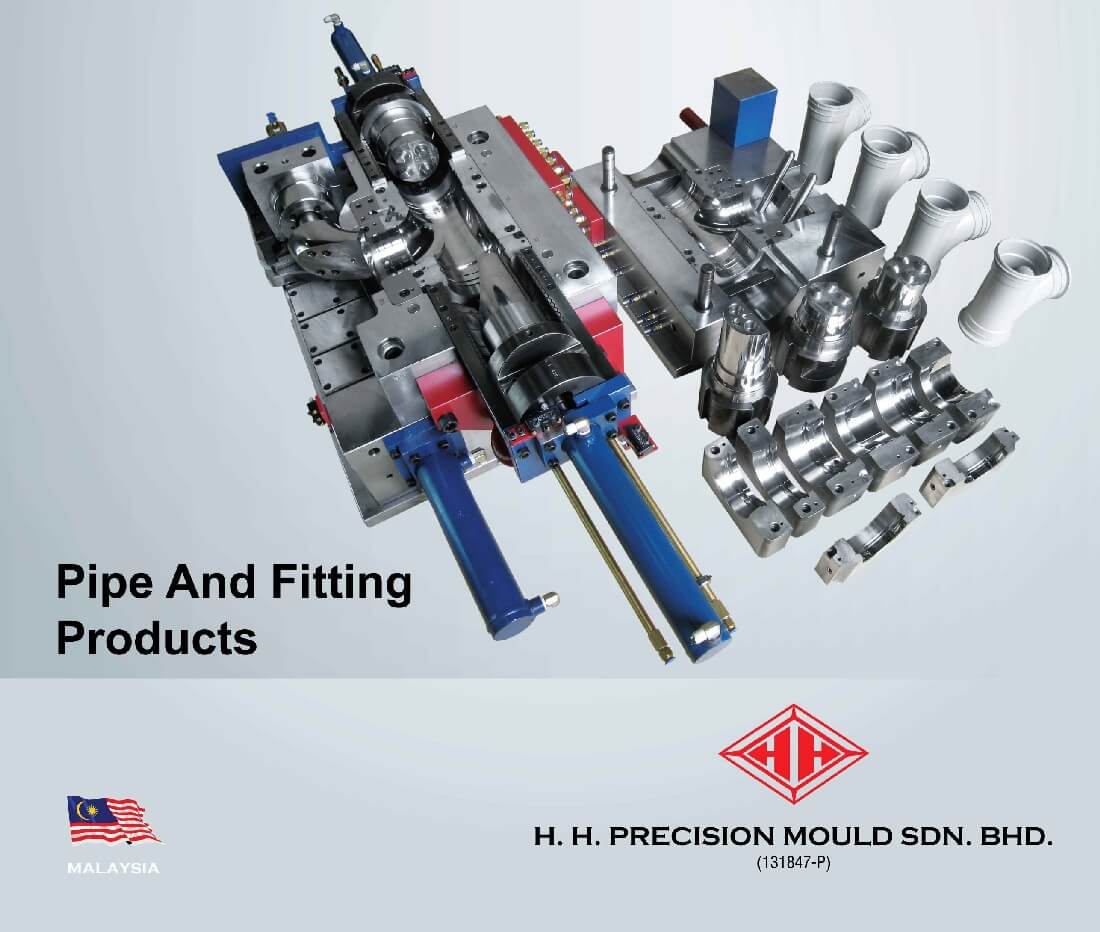

Moulds to the highest engineering standards

HH pipe fittings moulds are produced from high-grade steels from Böhler with the state-of-the-art machinery. The common fittings that we manufacture are depending on the application that can be screwed, plugged into or welded to the pipes – using electrofusion, cemented, socket or butt welding techniques,

HH are specialize in handling engineering plastic resins for pipe and fitting injected plastic parts. These material are PVC, UPVC, CPVC, PPR, PPSU, PE, PP, ABS, POM, PVDF, filled and fibre-reinforced materials.

The type of fitting mould manufacture by our company are:

- Water supply and drainage system.

- Soil, waste and vent (SWV) systems

- Underground sewage systems

- Random co-polymer pipe and fitting (PPRC)

- Electrical conduit and cable ducts

- Ventilation and exhaust system

Also, Our team assist customers to develop piping and fitting moulds accordance to their require standards. These standard are:

- British standard (BS EN1329, BS4514, BS4660, BS 5481),

- DIN stardard (DIN 19531, DIN19534),

- German DIN Standard (DIN 806263)

- ASTM standard (D 1785, D2241).

- JIS Standard

Our long term piping and fitting oversea and local customers are

- Georg Fischer (country: Switzerland)

- Qatar Plastic Additives Co. (country: Qatar)

- Paling-Aliaxis Group (country: Malaysia)

- Waterco (country: Australia)

- Brett Martin (country: United Kingdom)

- Marley (country: United Kingdom)

- Pt Wahana (Indonesia)

- Dux-Aliaxis Group ( New Zealand)

Note:

We have long term business relation in supply plastic injection molds to Georg Fischer (Switzerland) since 1996 till today.

We have closely collaborate with our GF mould technology team in Schaffhausen, Switzerland. Many Pipe and fitting mould making technology/know how from GF have impart to us. Our close cooperation enables us to make optimum use of synergies in order to improve processes and provide innovation solutions.

Fitting moulds that we have manufacture for our customer are: Elbow 90, Elbow 45, Branch 90, branch, Socket, End cap, P-trap gully, Equal Tee, Reducing Tee, Reducing Bush, Faucet Elbow, Tank Connector, Valve Socket, Double end socket, etc.